Description

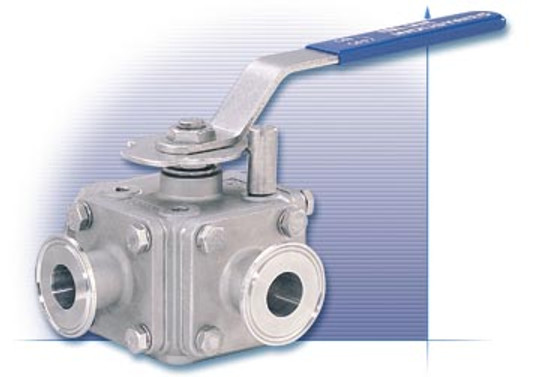

The 307F series utilizes a unique Tru-Drain tapered cavity body and integral purge and drain ports to eliminate potential pooling. This clean-in-place system provides outstanding performance in high purity applications.

Features and Benefits:

- Tru-Drain Tapered Body Cavity

Eliminates pooling of process media - Integral Purge and Drain Ports

Quickly drains body cavity - High-Cycle, Live-Loaded Stem Packing

Ensures tight seal

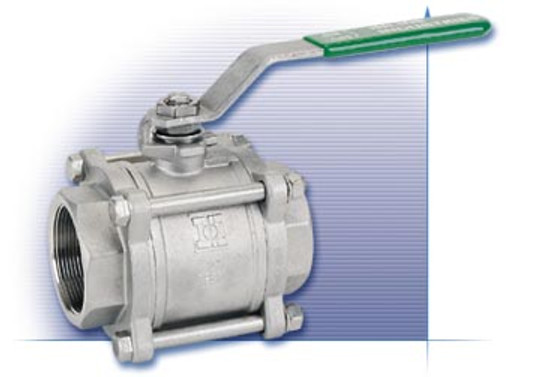

Extends service life - 3-Piece Swing-in-Place Construction

Easy to repair in service line - 316SS Construction with 316L Weld Ends

One valve can be used for many service conditions - Blow-Out-Proof Stem

Stem is bottom loaded to prevent removal when valve is in service - Locking Device

Enables plant personnel to secure valve in open or closed position when manually operated - Investment Cast

Improves dimensional control and reduces porosity - Internal Surfaces Roll Burnished Prior to Final Polish

Reduces surface porosity

Improves surface finish -

25 Ra Internal Surface Finish

Operating / Test Conditions:

- Temperature Range (PTFE): -20 to 350 F

- Maximum Working Pressure (PTFE):

1000 PSI (1/2"-1")

800 PSI (1 1/2"-2")

600 PSI (2 1/2"-4")

300 PSI (6") - Valves inspected and tested to API 598 and meet MSS SP-61 seat leakage requirements

- All materials comply with applicable ASTM material specifications and USDA and FDA material requirements

- Material test reports available upon request

Downloads